Computerized frame measurement systems revolutionize auto body painting and collision repair by providing accurate, efficient, and consistent data for precise frame straightening, enhancing accuracy, and delivering superior repair services. This technology also offers precise, objective assessments for car dent repair, streamlining initial inspections and categorizing dents accurately to improve outcome quality. Advanced computer vision technologies have transformed the industry, enabling informed decision-making through real-time data analysis, especially beneficial for complex designs and classic car restoration, and potentially reducing client downtime.

“Computerized frame measurement is transforming the precision of frame straightening, addressing industry challenges with innovative technology. This article delves into the intricacies of frame straightening processes and explores how computerized systems elevate accuracy.

We examine the traditional struggles with manual measurements and their limitations before showcasing the advantages of advanced computer vision. By leveraging these technologies, industries can achieve unprecedented levels of precision, revolutionizing frame straightening for various applications.”

- Understanding Frame Straightening and Its Challenges

- The Role of Computerized Frame Measurement in Enhancing Accuracy

- Benefits and Applications of Advanced Computer Vision for Frame Straightening

Understanding Frame Straightening and Its Challenges

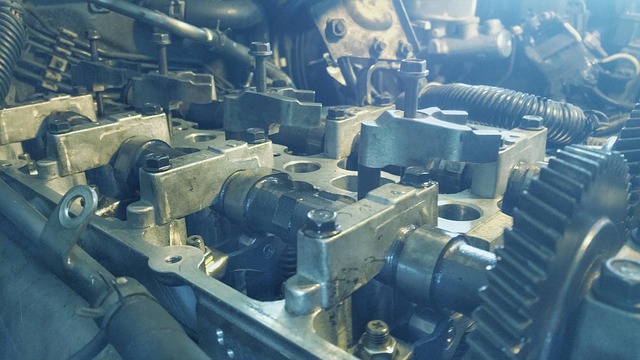

Frame straightening is a critical process in auto body painting and collision repair services, ensuring vehicles return to their original structural integrity after an accident or damage. It involves meticulously realigning and reshaping vehicle frames to restore their dimensional accuracy and safety standards. However, achieving precise frame straightening comes with its unique set of challenges. Traditional methods often rely on manual measurements and adjustments, which can be time-consuming, inconsistent, and prone to human error. This is where computerized frame measurement systems play a pivotal role.

Computerized frame measurement technologies offer a revolutionary approach by providing accurate, efficient, and consistent data. These systems use advanced sensors and software to capture detailed dimensions of the vehicle frame, allowing for precise identification of any deviations or damage. By digitizing the measurement process, auto body repair professionals can streamline their work, enhance accuracy, and ultimately deliver superior collision repair services. This advancement in technology is transforming the auto body repair industry, making frame straightening more efficient, reliable, and effective.

The Role of Computerized Frame Measurement in Enhancing Accuracy

Computerized frame measurement plays a pivotal role in enhancing the accuracy of car dent repair and auto dent repair processes. Traditional methods often relied on manual inspection, which could be subjective and inconsistent. In contrast, computerized systems provide precise measurements, ensuring every dent or scratch is accurately assessed for severity and location. This technological advancement is particularly beneficial in the intricate world of car scratch repair, where subtleties can make a significant difference in the final outcome.

By automating the initial assessment, these measurement tools allow technicians to focus more on the repair itself, streamlining the entire process. Moreover, the data collected during computerized frame measurement aids in developing effective strategies for both car dent repair and auto dent repair, ensuring that every imperfection is addressed with precision and care.

Benefits and Applications of Advanced Computer Vision for Frame Straightening

The integration of advanced computer vision technologies into frame straightening processes has revolutionized collision repair services and vehicle body repair procedures. This innovative approach offers numerous benefits, especially in enhancing precision and efficiency. With computerized frame measurement, auto glass repair and other intricate tasks become more manageable, ensuring optimal results.

Computerized systems can accurately detect even the slightest deviations from a vehicle’s original structure, allowing for precise adjustments during straightening. This level of detail is particularly advantageous when dealing with complex vehicle designs or restoring classic cars where maintaining historical integrity is paramount. Moreover, real-time data analysis enables technicians to make informed decisions, streamlining the entire repair process and potentially reducing downtime for clients.

Computerized frame measurement has revolutionized frame straightening, offering unprecedented accuracy and efficiency. By leveraging advanced computer vision technologies, this method overcomes traditional challenges, ensuring precise alignment and consistent quality in various industries. The benefits of computerized frame measurement are clear, from enhanced productivity to improved product reliability, making it an indispensable tool for modern manufacturing and construction practices.